Call Sales: +1 (833) 437-3835

Call Sales: +1 (833) 437-3835

Revel | June 24, 2017 |

Half of all small businesses use a manual method or don’t track inventory at all. The sheer number of businesses that do not have an accurate or even good idea of what their inventory looks like is a huge problem. Because of poor inventory management, businesses are losing sales, decreasing employee productivity, experiencing stock outs and ultimately frustrating their customers.

Investing in a robust inventory management system will not only save you money and customers, but put you ahead of half of all small businesses.

Revel introduced a new enhancement to our inventory management tool that gives business owners the ability to have the most precise look into their inventory.

Tracking Intermediate Inventory 101

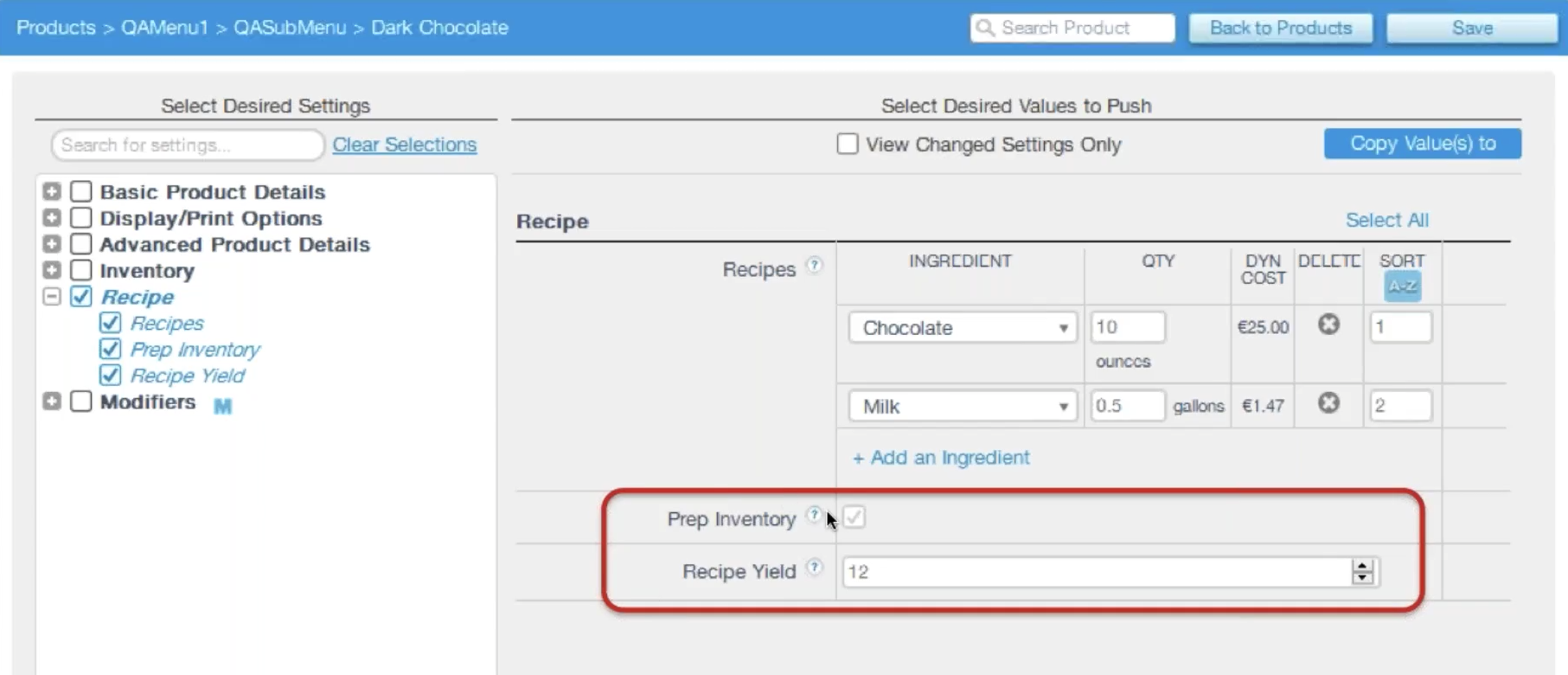

Revel’s latest feature, Prep Recipe, allows you accurately track your pre-made ingredient inventory. Through Intermediate Inventory, you can prepare ingredients/modifiers/products in advance by running recipes for each, ahead of time. You can then, enable “Prep Recipe” for each recipe, this way, the system will remove the individual ingredients from inventory as soon as the Prep Recipe is marked as prepared.

Previously, when inventory was reduced it was when the product was sold at the POS. But in reality, inventory loss starts as soon as the recipe is created, not just at the POS. Revel released a solution to this, by making sure that you can adjust the values of each ingredient, as well as the number of times it is run by the actual yield, to promote the most precise inventory measurement at the exact time the recipe has been created.

To initiate this process, begin by preparing a recipe as normal and then mark “Prep Inventory.” You can now also enter in the yield amount, to initiate an exact inventory count for a specific number of recipes. For example, you can check “Prep Recipe” for your dark chocolate bar recipe. The bar won’t cascade at the POS, rather the individual ingredients, example the milk and sugar, will be taken out individually once the recipe has been marked as “Prepped.”

Additionally, once you click on the recipe, you have the option to run the recipe in three ways:

Original Recipe: This is the default option. You can select how many times you want the recipe to be made, and the POS will show the affected yield amount.

Projected Input: You can run the recipe based on how much you have of a particular ingredient. For example, it will adjust the yield of recipes that can be made based off of how much sugar you have.

Projected Yield: You can run the recipe projected on how much you want to yield. If you want 30 chocolate bars it will tell you how much you want to take out of inventory for each ingredient.

At this level of inventory tracking you can better track spoilage and made in-house ingredients. From large supply vendors to last minute recipe adjustments, you can ensure that you’re getting a detailed picture of your inventory numbers.